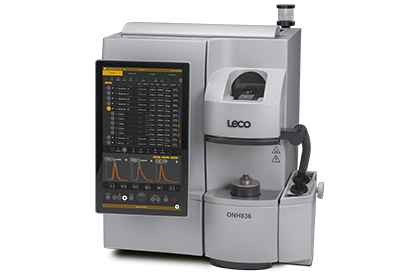

ONH Analyzer – LECO ONH836

Investigation method | Combustion analysis with subsequent spectroscopic detection of carbon and sulfur |

Abbreviation | CS Analyzer |

Device type and equipment | High-temperature combustion analyzer with infrared (IR) detection for carbon and sulfur |

Functional principle | The sample is combusted in an oxygen atmosphere at high temperature. Carbon and sulfur are oxidized to CO₂ and SO₂, which are quantified by infrared absorption detectors. |

Elements analyzed | Carbon (C), Sulfur (S) |

Typical applications | Metals and alloys, ores, minerals, cement, refractory materials, battery materials, and other inorganic solids |

Detection limit (Absolut amounts per sample) |

|

Measurement range | From trace levels up to high percentage concentrations (method-dependent) |

Requirements for sample | Approx. 1 g solid sample (powder, granulate, chips or pins); homogeneous and dry |

Sample throughput | Rapid analysis, typically a few minutes per sample |

Accuracy and precision | High accuracy and repeatability due to controlled combustion and IR detection |

Calibration | Calibration using certified reference materials (ISO17034) |

Accreditation / Certification | ISO17025 |

Advantages | Robust method, fast analysis, wide measurement range, reliable results for routine and quality control applications |

Using the LECO ONH analyzer, we determine oxygen, nitrogen, and hydrogen with high sensitivity and reproducibility.

We support our customers in answering questions such as:

- Steel: Determination of interstitial elements to assess material quality, cleanliness, mechanical properties, and suitability for further processing.

- Other metals and metal compounds: Analysis of oxygen, nitrogen, and hydrogen in metallic materials to support R&D, material development, and quality control.