Technical safety through dynamic testing

In many cases, dynamic tests are required to assess the behavior of materials and components in the real-world operation of products or assemblies. Therefore, potential fatigue must be modeled as realistically as possible.

Qualification for mechanical testing

Suisse TP tests materials in accordance with the relevant standards in the accredited area by means of dynamic tests. This is done either at room temperature or at high or low temperatures. Depending on the material and application, these types of tests are carried out in the high cycle fatigue (HCF) or low cycle fatigue (LCF) range.

Click here for materials testing.

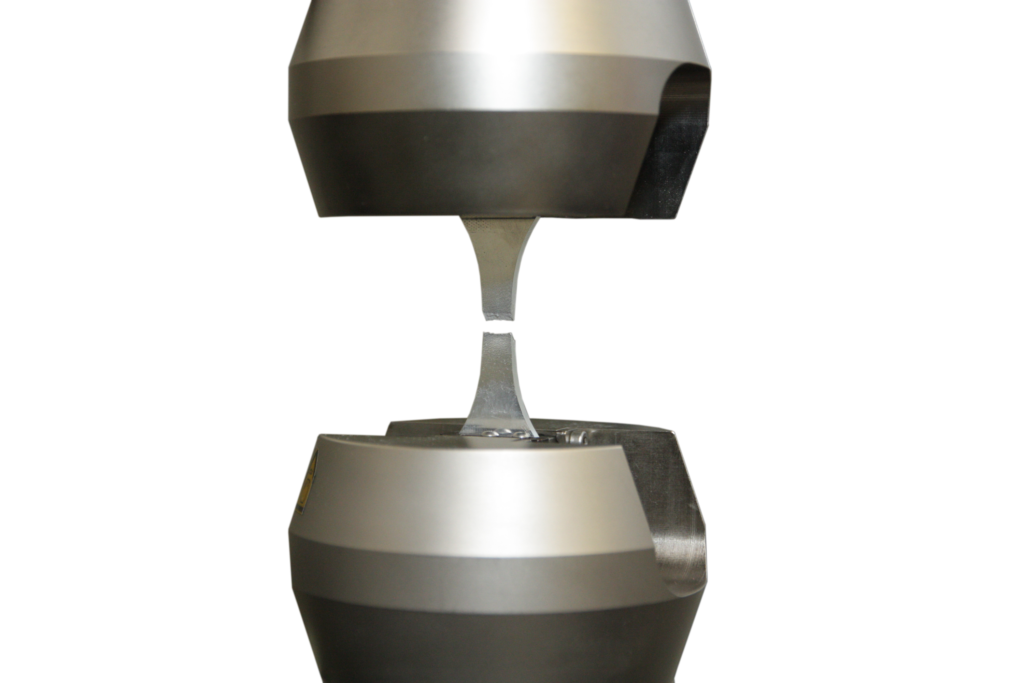

Components or component parts are often tested in the low-frequency range (LCF) by pneumatic or hydraulic cylinders in dynamic tests. In addition, some tests are carried out in resonance testing machines in the high-frequency range (HCF). Of course, this is only done if the component geometry and the materials used permit it. This is where we move on to component testing.

The dynamic tests, which have to be set up very carefully, require, on the one hand, structural-mechanical expertise for the correct application of force and torque during component testing. On the other hand, the highly qualified and specially trained employees also have the experience in setting up the appropriate measuring chains for monitoring and recording the stress.

The assessment of fatigue or damage to test specimens or components by Suisse TP’s experienced failure analysts is an important contribution to technical safety in product and process development.

Example applications for dynamic tests

dynamic tests for technical safety

In fatigue tests to determine Wöhler curves, e.g. aluminum alloys in the HCF range, high-alloy steels in the LCF range

In component tests to determine durability, e.g. chassis parts

Find out more about our expertise in the field of technical safety

You can find an overview of further methods in the field of technical safety in our encyclopedia – technical safety.