Filiform corrosion test according to DIN EN 3665 A 3

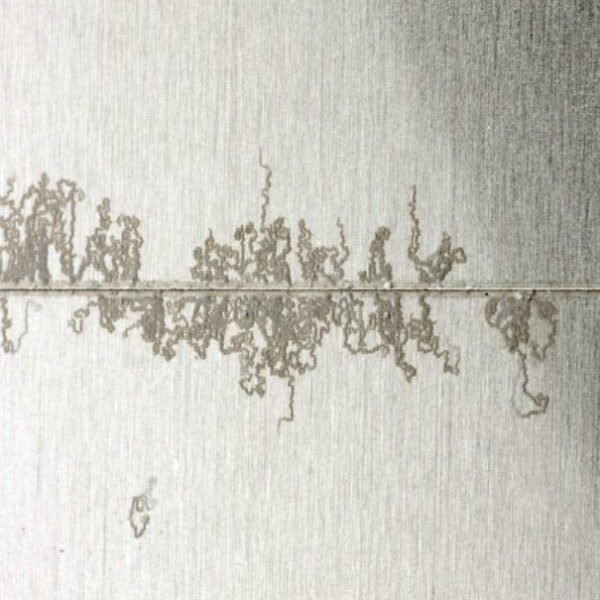

Evaluation of the protective effect of coatings on aluminum alloys against filiform corrosion. Also known as filigree corrosion, wormhole corrosion or snail trail corrosion.

Filiform corrosion is a special form of crevice corrosion that spreads in thread-like form. Typically, the 0.1 to 0.5 mm wide threads grow at a constant rate of about 0.4 mm per day.

| sample preparation | The varnish layer of the samples is damaged with the scratching tool according to Sikkens with two approx. 50 mm long scratches at a right angle to each other, which reach into the base material. |

| initiation | Inoculation of the samples for 60±5 minutes in a chamber containing HCl gas, followed by intermediate storage at room temperature for 30 minutes. |

| outsourcing | Horizontal storage of the samples at a temperature of (40±2)°C and (82±3)% relative humidity |

| test duration | As agreed |

| sample evaluation | Visual assessment of filiform corrosion according to DIN EN A3 |

Example applications for filiform corrosion

Salt spray tests for technical safety and aluminum surfaces

Organic coatings on aluminum and low-alloy steels are most often affected. Filiform corrosion is an issue for components used in coastal, marine or industrial atmospheres or in road salt applications.

Find out more about our expertise in the field of technical safety or in the field of aluminum surfaces.

You can find an overview of other methods in the field of environmental simulation in our encyclopedia – environmental simulation.