What is a tensile test?

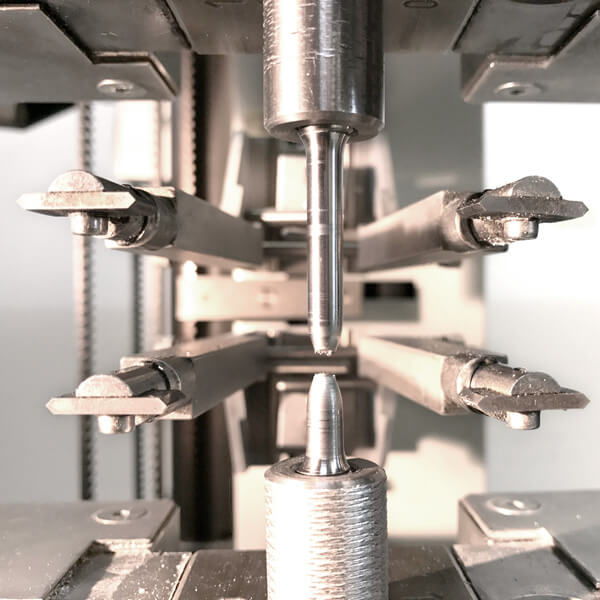

In a quasistatic tensile test, specimens are stretched at a low speed until they tear. This is why it is considered a destructive test method. During the test, the force on the specimen and the change in length in the measuring section of the specimen are measured continuously.

This makes it possible to determine characteristic values that are of great importance for the design and dimensioning of components subject to static loads. Based on these material characteristics, a comparison of material conditions or a material selection can be made.

In our ISO 17025-accredited testing laboratory, we usually determine material properties such as the modulus of elasticity, the yield strength (also known as the stretching limit), the tensile strength, the elongation at break and the necking.

If required, our mechanical workshop can machine round tensile test specimens or flat tensile test specimens from raw materials or components.

DIN EN ISO 6892-1 Tensile testing of metals (e.g. aluminum, steel)

The standards for the quasi-static tensile test on metals are differentiated according to various (four) temperature ranges. Suisse TP can be used to test up to 500 °C and up to 250 kN tensile force. The DIN EN ISO 6892-1 and ASTM E 8 standards are mainly used for the tensile test on metal or metallic materials at room temperature.

Tensile tests on metals at elevated temperatures are carried out according to DIN EN ISO 6892-2. For tensile tests at elevated temperatures, Suisse TP often measures strain using non-contact strain measurement (e.g. laser extensometers).

Tensile tests on plastics

Quasi-static tensile tests on plastics are defined in the ISO 527-1 to ISO 527-5 and ASTM D 638 standards. The special features of plastics in comparison to metals are the great influence of the pull-off speed and the temperature on the material behavior, as well as the change of the materials through aging. The standardized tensile tests are used primarily to compare different plastics. In real-life applications, the characteristic values determined by tensile tests at strain rates that deviate from those in the tensile test can only be used to a limited extent for design purposes. Furthermore, the standards are very good at comparing the change in material characteristics due to aging. Suisse TP can also be used to measure very small tensile forces (< 1 N) for plastic films, for example.

Tensile tests on composites

In principle, the test for composites in the form of fiber-reinforced polymers depends heavily on the fiber orientation.

There are therefore a number of standards that take into account the different types. (ISO, DIN, ASTM, CRAG, EN…).

For unidirectional fiber orientation or laminates, the strength in the fiber direction and the fiber composite or composite adhesion in the transverse direction are tested. To avoid damage (cracks) when clamping the samples, the tensile sample is often reinforced with gluing at the clamping areas.

For multi-directional laminates, the samples are made correspondingly wider (20 to 50 mm) and thus also significantly thicker (up to 10 mm) (ISO 527-4). This means that the required tensile forces are correspondingly higher. At Suisse Technology Partners, force ranges of up to 500 kN can be covered.

Due to their high stiffness, the requirements for specimen alignment and extension measurement for composites specimens are high for the required quality of materials testing. Therefore, strain gauges are often used for the extension measurement.

Material behavior determined in dynamic tensile test

In a dynamic tensile test or fatigue test, tensile specimens in the form of round or flat specimens are tested in our high-frequency (HCF) or low-frequency pulsators (LCF) under cyclic alternating loads. Wöhler curves (sn curves) for fatigue tests can be tested in the high-frequency range (test frequency up to 1000 Hz) as well as in the low-frequency range at temperatures up to 300 °C. The force amplitudes are up to 100 kN for HCF tests and up to 250 kN for LCF tests.

standardized test samples

Manufacturing standardized tensile test specimens of the required quality from a raw material or directly from components requires a high degree of care and experience.

Our test engineers define the appropriate specimen-taking locations together with the customer, taking into account the issues to be examined and the applicable standards.

If required, our mechanical workshop can also produce the corresponding round tensile test specimens or flat tensile test specimens with polished surfaces (for fatigue testing) or rolled threads for dynamic tensile tests.

If the specimens are to be tested for their creep behavior (relaxation), it is also possible to expose them to a constant static load in creep tensile tests at temperatures of up to 1,000°C.

Example applications for tensile tests

Tensile tests for technical safety

- Typical applications for the tensile test at Suisse TP include, for example:

- Determining material characteristics (such as modulus of elasticity, yield strength, hardening behavior, uniform strain, tensile strength, elongation at break, necking, etc.) for component design

- Determining the fatigue behavior of materials using Wöhler curves

- Evaluating the material properties of components in the event of damage

We are happy to advise you on how to achieve a high level of technical safety for your high technical requirements. We support you from the creation of a meaningful material specifications (specification), through the development of suitable (special) tests, to the professional interpretation of the results. Learn more about our expertise in the field of technical safety.