Analysis of surfaces

ANALYZING AND UNDERSTANDING SURFACES

We analyze aluminum surfaces from chemical composition to damage.

Chemical analyses are the fundamental prerequisite for the development of stable surface treatment processes. Our wide range of options in inorganic element analysis, organic analysis and polymer analysis perfectly support the work of our experts in many process steps.

Chemically analyzed

Alloy analyses, process bath controls and the determination of surface chemistry ensure consistent quality in operation;

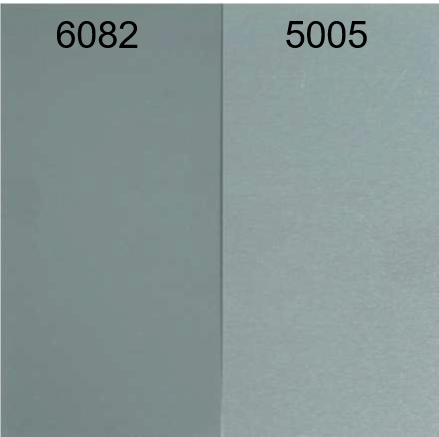

| 6082 | 5005 |

Alloy analyses

If there are differences in the surface despite the same baths and process parameters, different alloys may be the reason. . The alloy plays a significant role in surface treatments such as anodizing, polishing and colouring. In the example on the right, a 5xxx and a 6xxx alloy were anodized with the same parameters. The alloys deposit different alloying elements in the oxide layer, which is reflected in the color (grey tone of the oxide layer). We determine the alloy composition using spark spectrometry or wet chemistry.

Laboratory electroplating at Suisse Technology Partners

Process bath analyses

The composition of the bath is crucial for the development and reproduction of functional and decorative surfaces. For quality assurance, we use wet chemistry to determine various parameters that are crucial for a perfect surface with consistent quality. We use process bath analyses for: among other things

- Salary determination

- Proof of dye bath activity

- Detection of bath toxins

- etc.

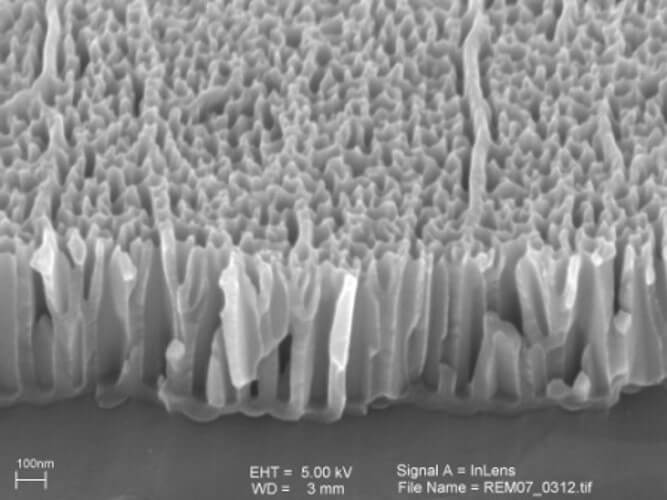

Surface chemistry

By determining the surface chemistry, we investigate chemical and structural processes that take place at the interfaces. This involves the elemental composition of the surface, as well as the concentration and distribution of the elements in the depth profile of the surface. This enables us to ensure that, for example, no residual surface impurities affect subsequent processes after degreasing and pickling. This is where our chemists and materials scientists make use of our various analysis devices, such as REM-EDX, XPS, FTIR, RFA.

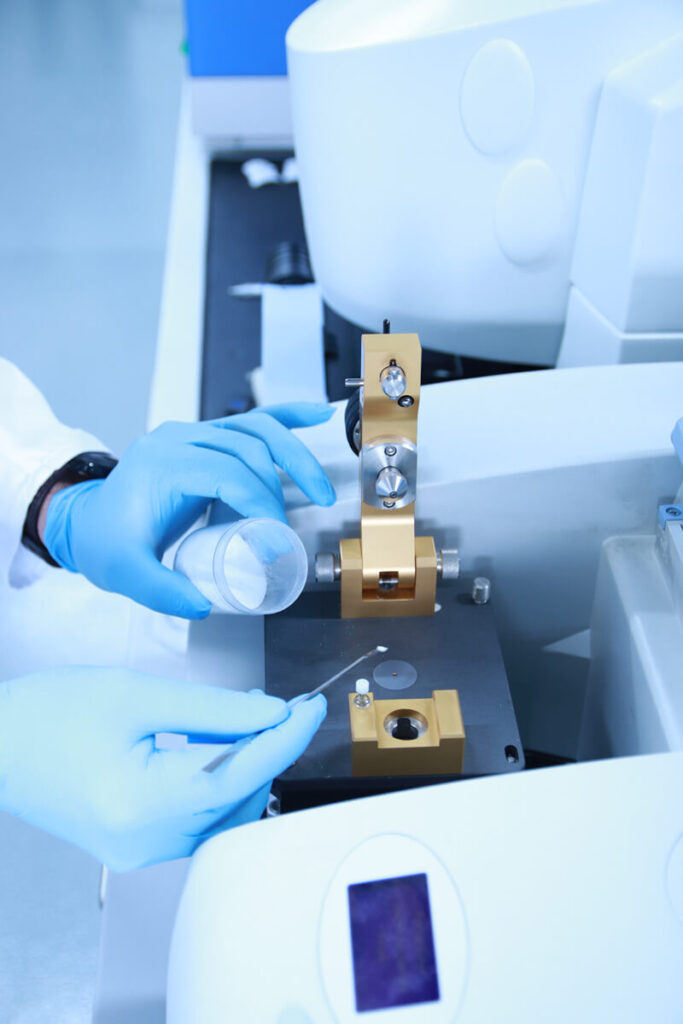

Analysis of the paint system

In our polymer laboratory, we are able to specifically examine the quality of your coating systems or any irregularities that occur. Depending on the results of the analyses, we can suggest optimizations for the process or the systems used.

For example, we examine the type of coating or composition on the basis of our FT-IR spectrometer, or the degree of curing with our thermogravimetric analysis (TGA).

With our scanning electron microscope(SEM), we can specifically analyze the distribution of pigments or particles.

Possible infiltrations of paint systems that are exposed to corrosion can be specifically examined for weak points in the coating structure.