Topic Overview

What is a composite inspection?

The term composite materials often refers to a wide range of different composite materials or material composites. The test methods for characterizing the materials used are correspondingly diverse. In order to use such composite materials in a technically safe manner, the material characteristics must be reliably determined in various tests.

Our composite experts have already successfully characterized, validated and optimized composite materials in our accredited laboratories.

A composite in the form of a sandwich with two outer layers and a core material can be characterized very well by bending tests with the resulting material properties of bending stiffness, shear stiffness, bending strength and shear strength. For the characterization of pure core materials in the form of polymer foams, additional tensile tests, compression tests, shear tests and density determinations can be carried out.

Fiber-reinforced plastics (FRP) or materials often referred to as ‘fiber-reinforced polymers’ (FRP) also fall under the term composite materials. Common forms of fiber-reinforced plastics are glass-fiber-reinforced plastics (GFRP) and carbon-fiber-reinforced plastics (CFRP). The fiber-reinforced plastics are characterized, for example, by the classical tensile test, the 3-point bending test or also by thermomechanical analyses such as the TMA or DMA. The fiber content of the samples can be determined by thermogravimetry (TGA) or Soxhlet extraction.

How is a composite material constructed?

Sandwich composite materials consist of a core and two outer layers. The materials used for the outer layers can be very different. Metals and fiber-reinforced plastics are commonly used, but paper or wood are also used as outer layers. These outer layers surround a core that consists of a solid material, a hollow material or a different structure, such as honeycomb.

A composite material combines the mechanical properties of the top and core layers in such a way that the desired material properties result. Very often, a high degree of flexural rigidity with minimal weight is desired.

Bending strength of composite materials

The flexural rigidity and flexural strength of composite materials (so-called core composites) can be determined according to DIN 53293 in the flexural test.

Compressive strength of core materials

The compressive strength of the core materials (usually rigid foam sheets made of polymer foams) is determined in the compression test. For this purpose, a piece of the core material is compressed between two plates in a universal testing machine. Various characteristic values such as compressive strength, compressive stress at 10% nominal compression and compressive modulus can be determined. The test is based on the ISO 844 standard.

Shear strength of core materials

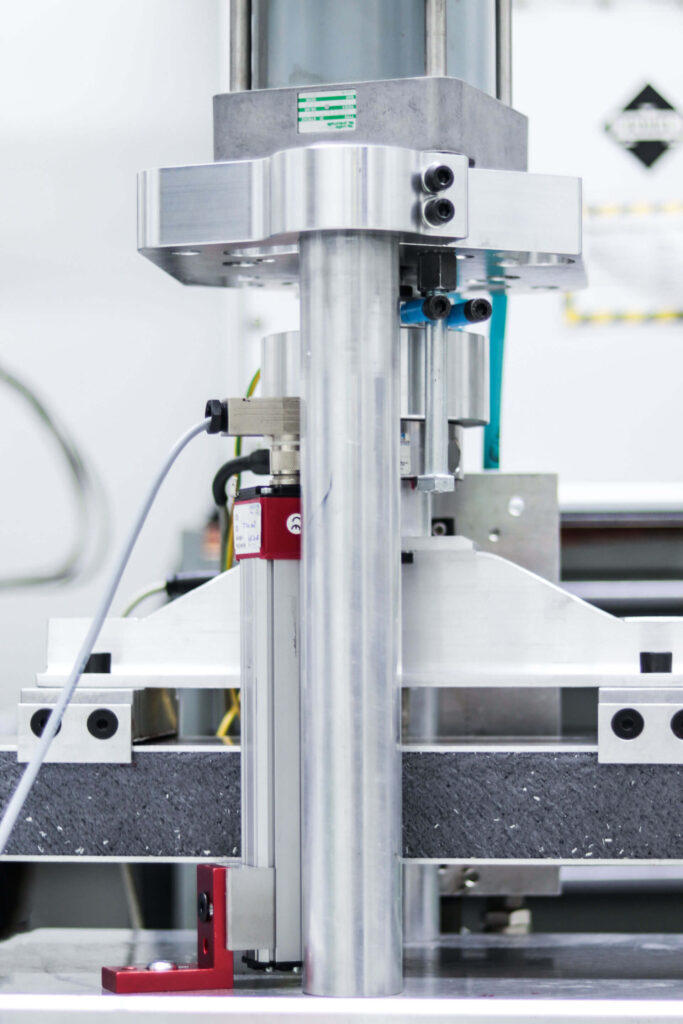

Shear stiffness and shear strength can be determined in both the bending test (with the appropriate sample geometry of the sandwich sample) and a dedicated shear test of the core material according to ISO 1922. In this test, the core materials are glued between two shear irons, which are then pushed against each other in a universal testing machine. Careful sample preparation and precise testing are of great importance here. At Suisse TP, the displacement of the shear irons and thus the shearing of the sample is measured without contact using a laser extensometer.

TENSILE STRENGTH OF CORE MATERIALS

The tensile strength of core materials is determined in the so-called head tensile test according to DIN 53292 (tensile test perpendicular to the surface layer plane). A sample of the core material with a top layer is taken from the sandwich and glued between two steel blocks. These are mounted flexibly in a universal testing machine and pulled apart. This allows characteristic values such as tensile strength, yield strength and tensile stress at a certain strain to be determined. The fracture pattern can also provide information on adhesion problems between the top layer and the core material.

Example applications for composite material testing

Composite material testing for technical safety

Numerous tests (bending tests, pressure tests, head tension tests, TMA, TGA) on composite materials are carried out for the following products to ensure the required material properties for safe operation:

Polymer foams in sandwich applications for wind turbines and vehicle bodies

Sandwich for vehicle bodies, caravans and other lightweight applications

Sandwich structures for rail vehicles

Aluminum composite panels for building facades or display applications

Find out more about our expertise in the field of technical safety