Hardness test at Suisse TP

Suisse TP, an ISO 17025 accredited testing laboratory, offers professional hardness testing services. Our independent analyses are based on scientific methods and carried out by qualified metallographers and materials scientists. This expertise enables us to provide accurate and reliable results.

Our laboratory’s accreditation guarantees compliance with high quality standards. Our team has the expertise to carefully carry out each hardness test and to interpret the results in the context of specific customer requirements.

We offer our customers not only data but also advice to ensure the quality and reliability of their metal products. Suisse TP stands for precise hardness testing with a focus on quality and expertise.

by Vickers

Vickers hardness testing is a component of material testing in metallography. At Suisse TP, we carry out this test with the highest precision and in an accredited manner to ensure accurate hardness data for a variety of metals and alloys. Usually according to the DIN EN ISO 6507-1 standards.

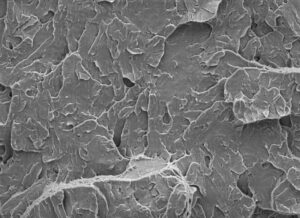

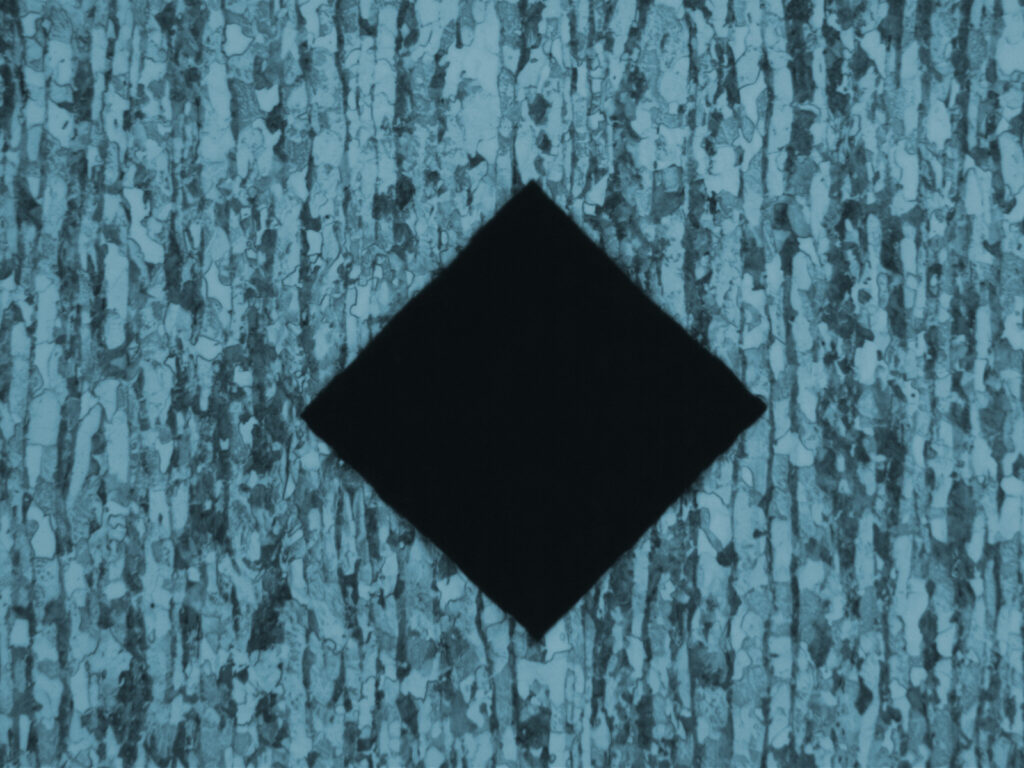

The Vickers method, also known as microhardness testing, is particularly suitable for materials with very small test surfaces or thin layers. It is based on the principle of pressing a diamond pyramid tip into the material and measuring the depth of penetration. The resulting impression area is evaluated microscopically to determine the Vickers hardness number (HV).

This method is particularly valuable due to its high accuracy and reproducibility. It is suitable for a wide range of applications, from examining thin coatings to evaluating the hardness of weld seams.

by Brinell

Brinell hardness testing is a traditional and widely used method for determining the hardness of materials, especially for softer metals such as aluminum, copper and unalloyed steels. Suisse TP performs Brinell hardness testing in accordance with recognized standards such as DIN EN ISO 6506-1 or ASTM E10 .

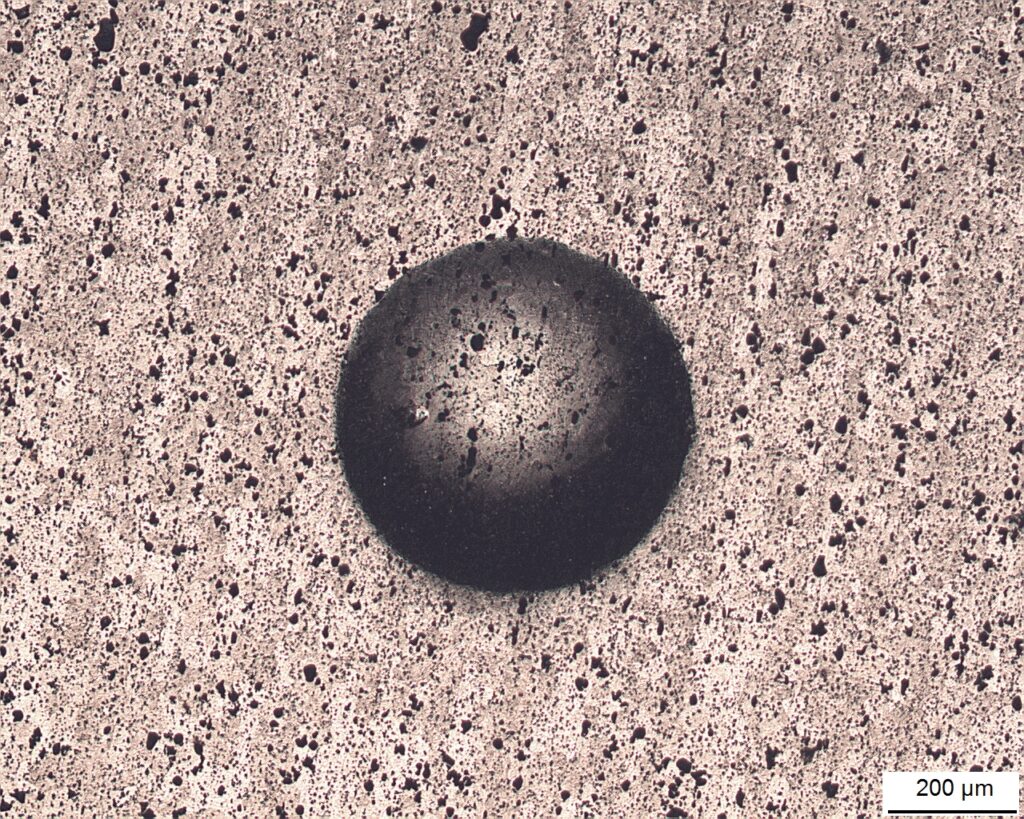

The procedure uses a hardened steel or carbide ball that is pressed into the material under a defined load for a specified time. The resulting impression surface is measured and used to calculate the Brinell hardness number (HB). This number is derived from the ratio of the applied force to the surface of the impression.

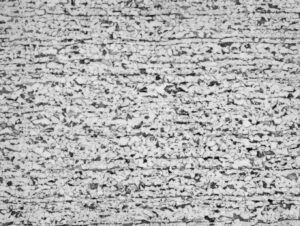

The Brinell method is particularly suitable for materials with a coarse-grained structure, since the larger impression area provides a more representative measure of the average hardness of the material. This method is robust and less sensitive to the surface condition of the test piece than other hardness testing methods.

martens hardness

Martens hardness testing is an advanced and specific method for determining the hardness of materials and is used for special requirements. The ISO 14577 standard is often applied. This test method is particularly relevant when dealing with fine-grained materials or composite materials where conventional hardness testing methods reach their limits.

The Martens hardness (HM) method is based on the principle of continuously increasing and measuring the load. Unlike traditional hardness testing methods such as Vickers or Brinell, which apply a constant load for a specified time, Martens hardness increases the load continuously while simultaneously measuring the penetration depth of the indenter. This method makes it possible to determine the hardness as a function of depth, which provides detailed information about the elastic and plastic behavior of the material.

The Martens hardness test is particularly useful for examining surface layers, thin films or coatings. It offers high resolution and sensitivity, making it ideal for characterizing heterogeneities and phase transitions in materials.

| Device type and equipment | DuraScan G5, Fischerscope and Brickers 220 |

| Vickers | DIN EN ISO 6507-1 , micro and small loads |

| Brinell | DIN EN ISO 6506-1 , ASTM E10 |

| martens hardness | ISO 14577 |

| Typical applications | Determining the case depth (CD), nitriding depth (ND), surface hardening depth (SHD), core hardness and heat treatment conditions |

Methods that might also interest you

You can find an overview of other methods from the various fields of metallography and surface technology in the corresponding sections.