Component testing

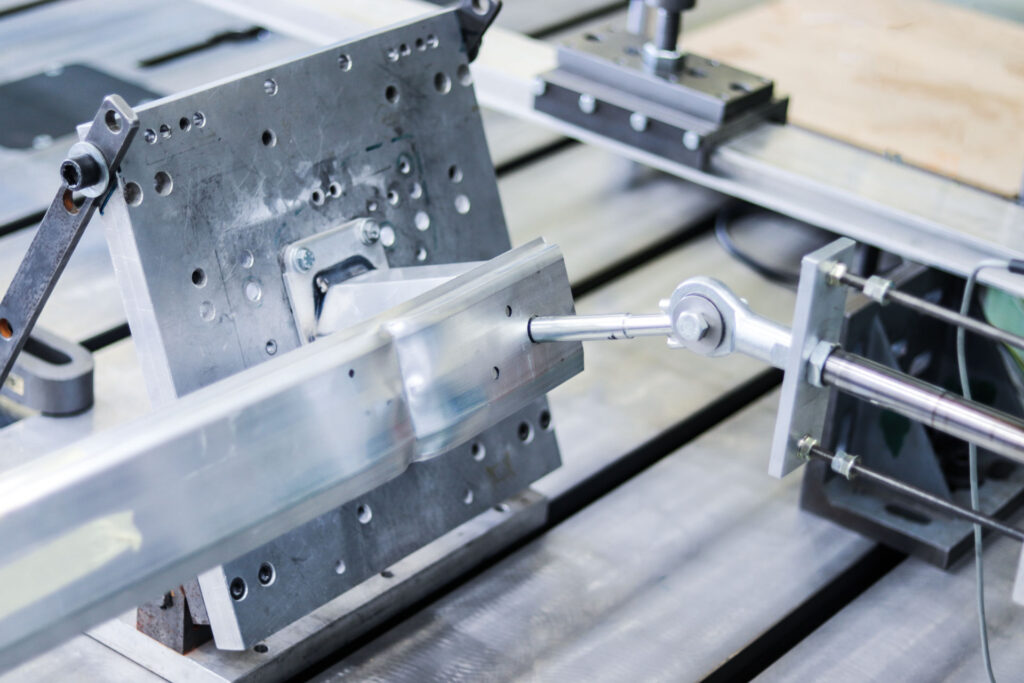

The aim of a component test is to stress parts and components with replacement loads or load spectra in such a way that the real load in series use is simulated as closely as possible.

This serves to ensure technical safety in series production. As a rule, the components are loaded in the test until failure. From this it can be deduced whether component failures are to be expected in the field or not.

The failure of the component can have various causes, constructive, mechanical, chemical or thermal.

That is why we do not leave our customers alone with the results of the test and the optimization of the problem. We can compare the results obtained with idealized boundary conditions in an FEM simulation and, together with the assessment and recommendation of our damage analysts, material and surface experts, optimize them for stable series use.

COMPONENT TESTING FOR SAFETY AND CONFIDENCE IN YOUR PRODUCTS

Accredited and certified results from component tests create trust and safety for products in series production. That is why we are not only independent but also accredited in accordance with ISO/IEC 17025 . The highest flexibility level (Type C) allows us to develop and carry out accredited customer-specific special tests.

Experts from various disciplines Engineers, materials scientists, metallurgists, (polymer) chemists with many years of experience bring all their expertise to the processing of technical, customer-specific requirements. With the aim of making products safer.

A wide range of different methods with corresponding expertise enable a targeted approach to the validation or optimization of your products.

OUR STRENGTHS IN THE FIELD OF COMPONENT TESTING

- For components, the material-compatible design is in the foreground. We advise on the selection of suitable materials and for a material-compatible design with regard to service life, corrosion and wear behavior (tribology).

- We provide support in creating the specification of materials, semi-finished products or raw materials and also create the necessary test specifications. This is important for meaningful incoming goods inspections to ensure stable series production.

- We can carry out realistic component tests accordingly on our own test field. Very often special tests are also required to put components through their paces. Thanks to ISO/IEC 17025 type C, these can be carried out on a customer-specific yet accredited basis. Our engineers define such tests in close cooperation with the customer, our test laboratory and with great care.

- This also includes environmental simulations ( temperature, humidity, corrosive environment) of components, which can also be combined with mechanical loading.

- The tests can be compared with an FEM simulation (idealized boundary conditions) in order to largely rule out unforeseen influences in complex test setups.

- The strength and durability testing of joints (welded joints, bolted joints, rivets, bonded joints) are an important part of the validation of components (e.g. rotating bending tests of welded joints)

- Local material characterization on the component is carried out on the one hand by defining the relevant component area subject to high structural mechanical stress and on the other hand by carefully removing test specimens (incl. mini specimens) (e.g. without inadmissible heat input). This is a prerequisite for the correct evaluation of the local material and service life properties (tensile strength, yield strength, modulus of elasticity, ductility, fatigue LCF and HCF, creep behavior, high-temperature strength, …)

- The material tests are carried out for metals, polymers and composite materials (composites) or material composites (e.g. sandwich) for our customers.

- Inspection and condition assessment of components, assemblies and systems are carried out by our experts on site if required

EXAMPLES WHERE WE ENSURE SAFETY

- Series approvals of statically and dynamically highly stressed components:

- Steel cables in continuous operation

- Window frames in load-bearing side components (e.g. of buses)

- Towing devices (automotive)

- Cable crush test (mechanical short-circuit test) on car charging cables

- Stress test e.g. on chassis parts

- Adhesive joints on extractor hoods

- Component optimizations:

- Identification of weak points and targeted optimization through realistic component tests, e.g. for fastening photovoltaic systems

- Validation of new material developments in application, e.g. of new sandwich core materials in the wind power and transportation industries (static and dynamic shear and bending stiffness, service life behavior)

- Welding suitability tests of light metals used in the car body for safe series production at premium manufacturers in the automotive industry

- Process optimization with regard to optimum component properties of highly stressed forged components, e.g. in the aviation industry