Themenübersicht

Fatigue testing at Suisse TP

In the testing laboratory at Suisse TP, accredited fatigue tests are carried out in accordance with ISO 17025.

Very careful sample preparation for the fatigue test is ensured in our own workshop on the basis of the various standards. Our extensive experience in the quality of the test specimens is an important prerequisite for reliable results when determining, for example, S-N curves for the materials used.

At Suisse TP, a wide range of materials and components are tested for their fatigue behavior: aluminum, steel, copper, titanium, nickel, plastics, fiber composite materials (GRP, CFRP), foams and sandwich composites.

Typical dynamic fatigue test

- Fatigue test (Wöhler fatigue test) according to DIN 50100

- Low Cycle Fatigue Test LCF

- High Cycle Fatigue Test HCF

- Rotating bending test according to DIN 50113

- Full Scale Fatigue Tests

Typical material properties that are determined

- Wöhler curve / Wöhler diagram

- operational stability

- vibration resistance

- low cycle fatigue strength (LCF)

- high cycle fatigue strength (HCF)

- fatigue strength / fatigue resistance

Fatigue testing

Testing equipment/options

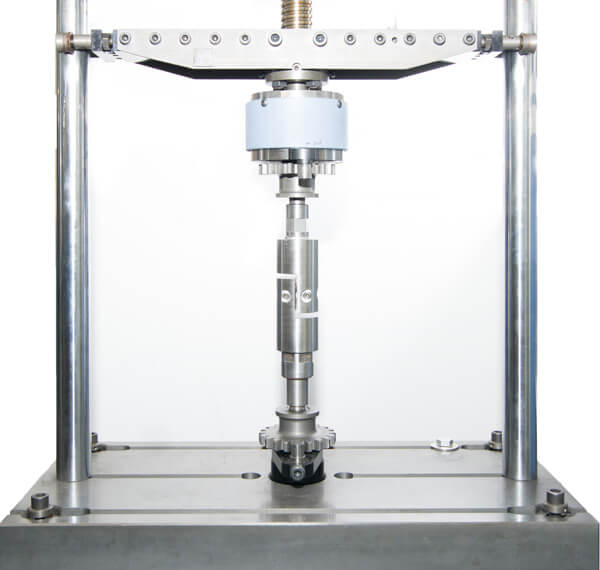

For single-axis stressed samples and small components, various testing machines are available that are operated either with servo-hydraulic cylinders or with resonance drive. Our testing equipment is kept in perfect condition through regular maintenance and calibration with the appropriate force and distance standards. In addition, the results obtained are verified in the context of accredited round robin tests.

The following dynamic tests and fatigue tests can be carried out on test specimens and small components:

HCF - High Cycle Fatigue

The oscillation system consisting of the specimen/component and the testing machine must be tuned in the initial phase of the fatigue test.

Our high-frequency pulsators work in a

- measuring range or force range from 2kN to 200kN

- with stress ratio -1 ≤ R ≤ +1

- test frequency 50Hz ≤ f ≤ 1’000Hz depending on the natural vibration behavior

Typical applications include testing the fatigue strength or endurance limit of materials or components and thus creating S-N curves.

Typical test standards are, for example, ISO 1099 or ASTM E466.

LCF - Low Cycle Fatigue

LCF fatigue tests are performed at lower frequencies and have the advantage that even the first load is applied correctly. Force- or displacement-controlled tests are possible.

Our servo-hydraulic testing machines with test frames work

- with a measuring range up to 250kN

- a stress ratio -1 ≤ R ≤ +1

- a test frequency f ≤ 40Hz depending on the sample

Typical applications include tests of materials or small components for time-related strength, in particular short-term strength.

Hydraulic testing systems are also used in particular for component testing under operating loads (detailed specified loads with different sequences of cycles).

rotating bending testing machine

The fatigue strength of materials can also be determined using a rotating bending test. (max. load = 26 Nm, 1-200 Hz)

The following standards are used, for example:

- ISO 1143 “Metallic materials – Rotating bar bending fatigue testing”

- DIN 50113 “Testing of metallic materials – Rotating bending test”

In rotating bending at room temperature, round samples of metallic materials are subjected to alternating loads with a constant load amplitude.

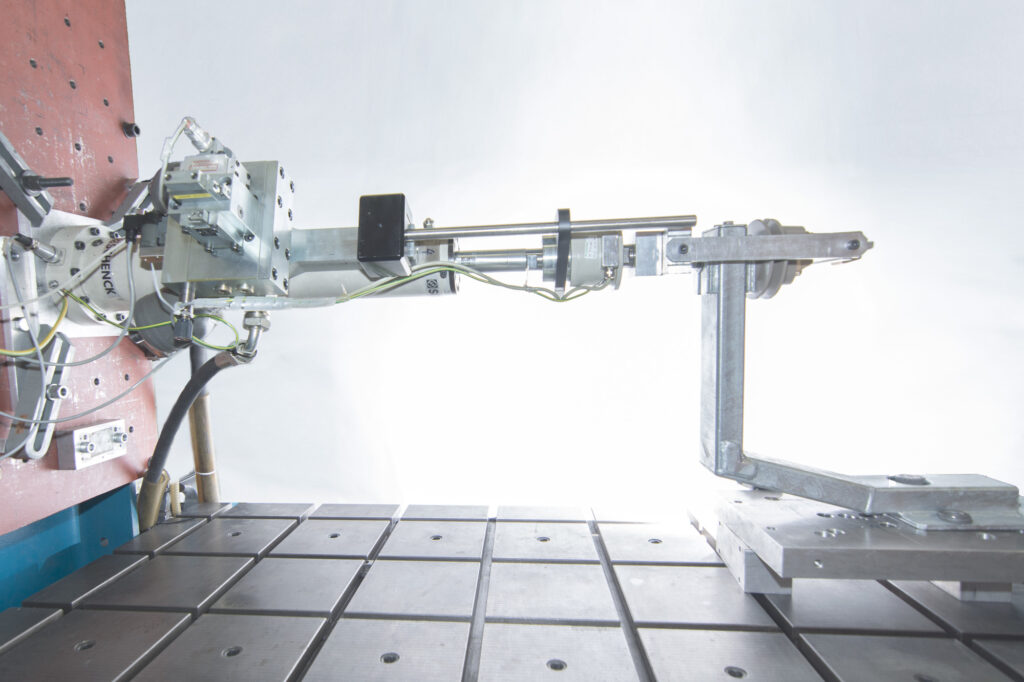

test voltage frame and test bay

Complex tests on parts or components in the testing frame and on the clamping field. The number of forces and force directions are flexibly initiated by synchronously controlled hydraulic or pneumatic cylinders, depending on the requirement and force level.

- Multi-channel control

- Testing frame (L x W x H = 3m x 1m x 2m)

- clamping field (L x W x H = 6m x 5m x 4.2m)

- Hydraulic cylinder (dynamic up to 100 kN, static up to 1’000kN)

- Pneumatic cylinder (static up to 17kN)

Components are loaded under realistic conditions using testing cylinders. The component is monitored during the test.

The necessary fixtures and clamping devices are manufactured in our own prototype workshop as required.