MECHANICAL DYNAMICS ANALYSIS

Determining the temperature- and frequency-dependent viscoelastic properties

investigation method

dynamic mechanical analysis

abbreviation

DMA

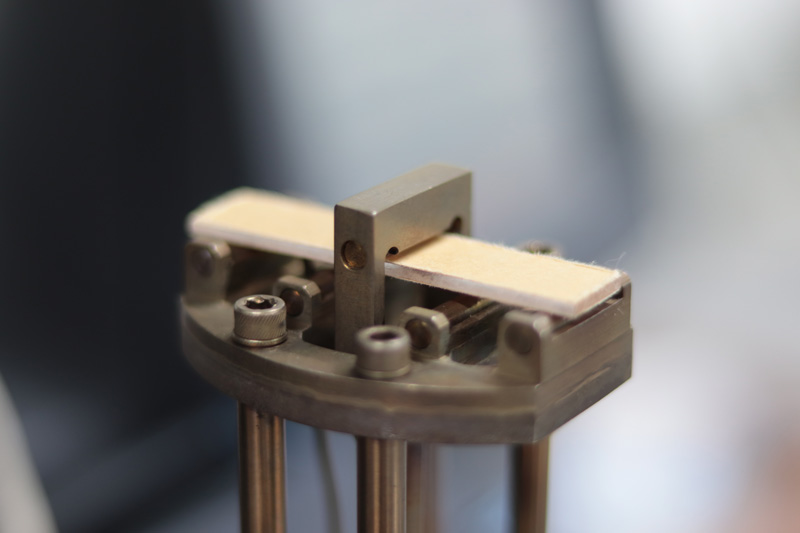

Device type and equipment

DMA Q800 with GCA cooler (TA Instruments)

functional principle

The viscoelastic properties are determined as a function of frequency and temperature by applying an oscillating force to the sample.

Typical applications

Plastics, composites, resins, material and product development, simulation, automotive industry, medical technology, aerospace, electronics

measurement technology

Dual/single cantilever, three-point bending, shear sandwich, compression, tension. Measurement modes: isodeformation, multifrequency, creep/stress relaxation, multideformation/stress, controlled force/deformation rate.

Requirements for sample

individual, depending on the measurement method

Norms and standards

DIN EN ISO 6721-1, DIN 53440, DIN 53513, ASTM D 4065-90, ASTM D7028-07

Example applications for DMA

Determining viscoelastic properties: DMA enables the precise characterization of the viscoelastic properties of polymers. It can measure elasticity, stiffness, viscosity and damping properties, which helps to understand the deformation behavior and structural changes of polymers under different conditions.

Identifying glass transition temperatures: DMA is particularly useful for determining the glass transition temperature (Tg) of a polymer. This information is important for understanding the temperature ranges in which a polymer changes its mechanical properties. This is particularly relevant for applications where temperature changes occur, such as in the automotive industry or in electronic devices.

Investigating polymer reinforcements: DMA can be used to evaluate the effectiveness of polymer reinforcements such as fibers, fillers or nanoparticles. It allows the study of the influence of these reinforcements on the mechanical properties of the polymer, such as stiffness and strength.

Quality control and comparison: DMA can be used to ensure the quality of polymers by comparing the mechanical properties of different samples. It can detect discrepancies in viscoelastic properties between different batches or manufacturers, which aids in the selection of suitable polymer materials.

Material development and optimization: DMA plays an important role in the development of new polymeric materials or the optimization of existing ones. By analyzing the viscoelastic properties in detail, engineers can adjust the composition and manufacturing parameters to achieve the desired mechanical properties for specific applications.

DMA for technical security

DMA enables a detailed analysis of the mechanical properties of materials and components, which leads to improved technical safety of products and processes. By identifying potential weak points at an early stage and optimizing design and manufacturing processes, DMA helps to bring safer and more reliable products to market. Alternatively, we can also determine mechanical properties using static (tension testing, compression testing, bending testing…) and dynamic (e.g. fatigue testing, rotating bending testing…) methods.

Our experts know exactly which method best suits your requirements. Give us a call.

An overview of further methods in the field of polymer analysis can be found on the page – polymer analysis.